Feeders

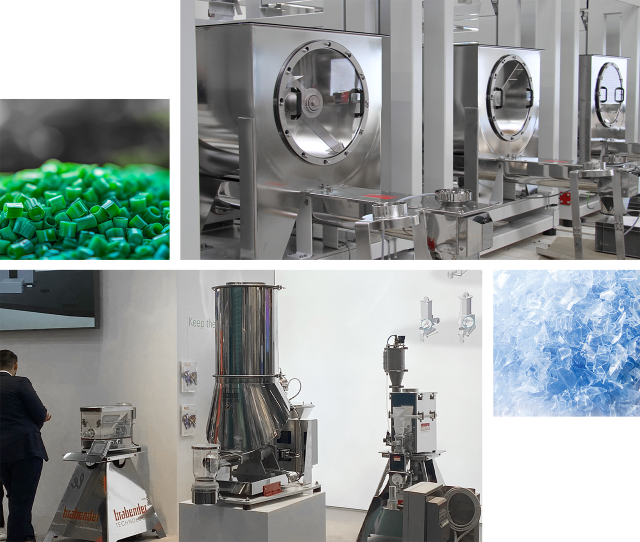

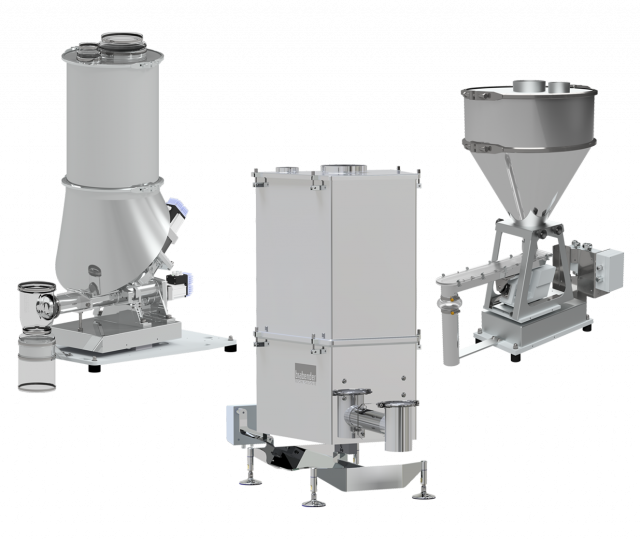

With our gravimetric and volumetric high-tech feeders, we offer various solutions for automatic, continuous, or batch-accurate dosing of bulk materials. These systems support single or multi-component weighing based on the “loss-in-weight” principle.

Our gravimetric feeders stand out for their reliable bulk material flow and high dosing accuracy for all types of bulk goods. Kubota Brabender Technologie’s loss-in-weight feeders and belt scales also handle the most challenging cases: the wide range of dosing equipment – including single and twin screw feeders, vibrating tray feeders, belt scales, and liquid feeders – ensures safe and precise dosing of a variety of materials. All of our loss-in-weight feeders are also available with integrated weighing systems and microprocessor controls. Thanks to their easy-to-clean design, our reliable and high-quality devices are ideally suited for quick product changes.

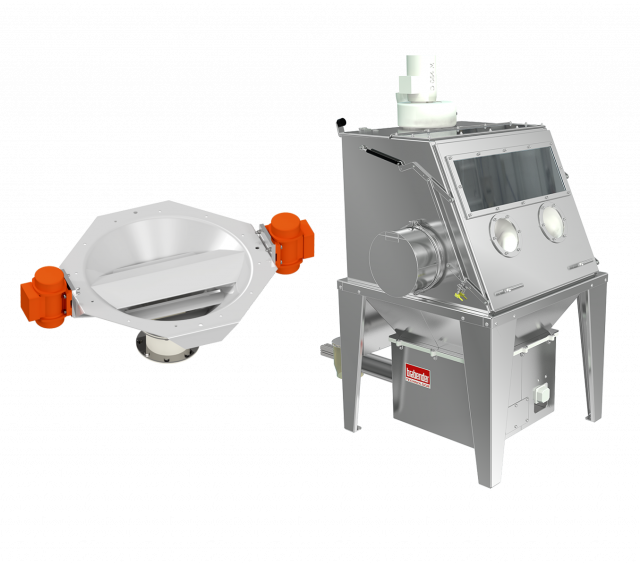

Efficient Discharge Aids for Uniform Bulk Material Flow

Bulk materials differ significantly in flow behavior – especially during storage and discharge. If compaction occurs, for example when emptying from silos, the entire production process can come to a halt. Discharge aids ensure a continuous material flow and prevent process disruptions.

Whether sacks, big bags, silos, or containers – modern discharge aids enable reliable emptying of a wide variety of materials. Even with poorly flowing or interlocking bulk solids, they ensure a smooth and efficient process.

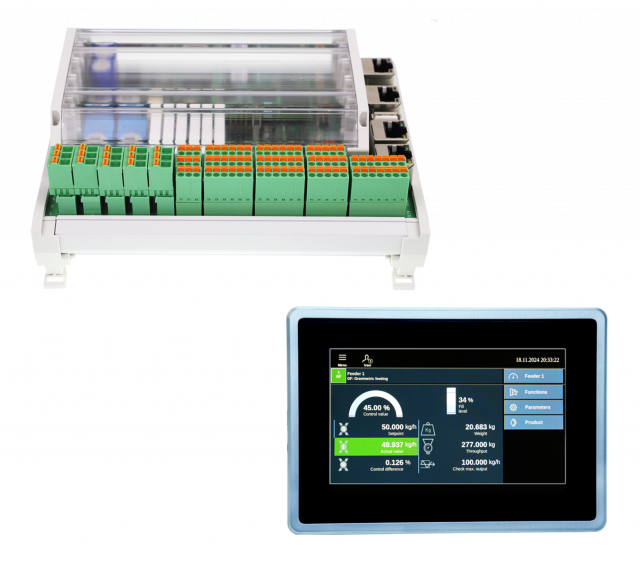

Intelligent Control for Precise Feeding Processes

Fully automated feeding requires more than precise weighing technology – smart control systems with modern software and flexible interfaces are essential. They coordinate the interaction between weighing and control functions and seamlessly integrate feeding scales into existing systems – including filling components, shut-off valves, and more.

In addition, they enable comprehensive process documentation – indispensable for quality management, traceability, and certification.

Scalable for any requirement

Whether single or multi-component control: the systems are flexibly deployable – either directly on the feeding scale or in a control cabinet. Up to 16 feeders can be efficiently managed and networked within one process line.

Equipment that Perfect Processes

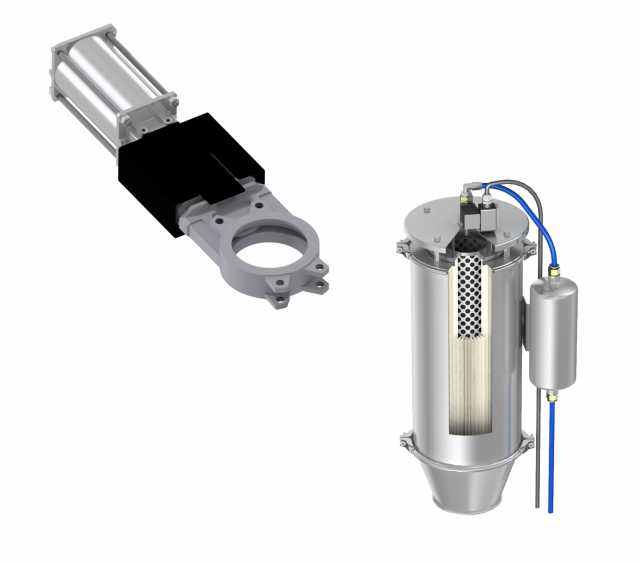

From feeders to discharge aids – a well-thought-out range of accessories ensures the optimal complement to your bulk material technology. Practical components enhance existing systems and improve efficiency, safety, and ease of cleaning.

For example, the flat slide gate: an automatic filling gate with a double-acting pneumatic drive – ideal for shutting off bulk material flows, such as in loss-in-weight feeders. Or the JetFilter: a powerful filter cartridge made of FDA- and GMP-compliant polyester felt for efficient exhaust air cleaning in dusty processes.