Technical details

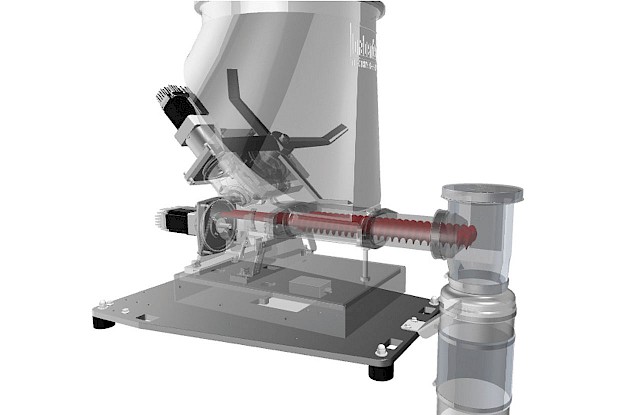

- Handles poor-flowing, sticky powders as well as fibers and pellets

- A special negative angle wall hopper geometry and an diagonal agitator that prevents bridging and ensures optimal bulk material flow into the screw

- Optimized mass flow and a uniform screw fill level

- An add-on hopper for a total bulk storage of 110 dm³ (3.9 cuft)

Power Range

- 10–2000 dm3/h / 0.35–70.63 cuft/h